Making and maturing cheese

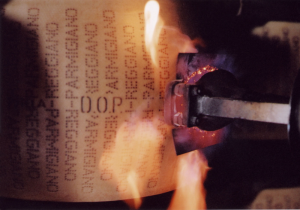

The evening milk is left to rest until the following morning in large tanks, in which the cream spontaneously rises to the surface; this will be used for making butter. The morning milk is then added to the skimmed evening milk before being poured into copper tanks. The expert cheese-maker adds the veal rennet and the whey starter culture, rich in natural milk enzymes, obtained from the previous day’s cheese-making process. He then uses a traditional instrument known as a spino to break up the curd. It is at this point the cooking process begins, reaching a temperature of 55° C, which ends with the formation of a curd mass that the cheese-maker removes and wraps in a cloth, dividing it into two parts, known as gemelle, or twins. The cheese is then placed in a mould (fascera) where it will acquire its final shape and be stamped with a casein mark featuring all its identification details. In the evening, while the wheel of cheese is still soft, the quality mark of the Parmigiano Reggiano Consortium will be added. Three days after production, the wheels are placed in brine, where they will remain for 20 days. Once they have been salted, they will be stored in the warehouse for maturing. When left to rest, the cheese dries out and forms a natural crust. It is matured for a minimum of 12 months.